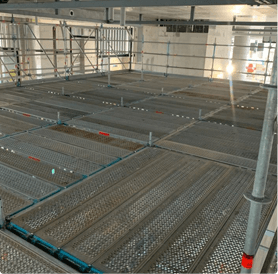

Kwikstage is a secondary scaffolding solution that we employ for our projects where Layher isnt available or appropriate. Kwikstage is a modular scaffold system that is widely used in the construction and building industry. It is known for its safety, design flexibility, and stability. Kwikstage scaffolding is quick and easy to assemble, which makes it ideal for use on construction and industrial projects where time is of the essence.

Kwikstage scaffolds are also made from high-quality materials that meet all safety standards, making it a safe option for both commercial and residential construction projects. In addition, Kwikstage scaffolding is highly versatile and can be adapted to suit the specific needs of any building project. As a result, it is one of the most popular scaffolding systems on the market today.