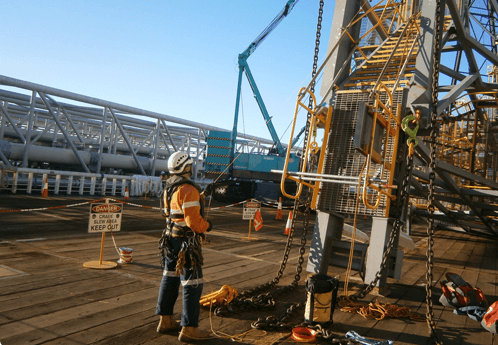

APS Industrial Services provides a range of structural, mechanical, fixed plant maintenance and piping services to our clients across the energy, infrastructure, and renewables sectors. When combined with our steel erection, rigging and site welding capabilities and supported by our range of scaffolding and specialist access systems, APS is a leading provider of world-class project, campaign or ongoing maintenance services across a range of assets and sectors.